DISSOLVED AIR FLOTATION (DAF) TECHNOLOGY

DAF stands for Dissolved Air Flotation, which is a wastewater treatment technology used to remove suspended solids, fats, oils, and greases from industrial and municipal wastewater streams.

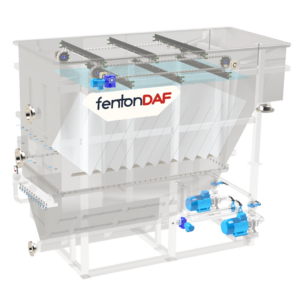

Fenton Technologies Dissolved Air Flotation (DAF) System is a reliable and versatile water clarification system. It employs a combination of dissolved air, chemicals, and mechanical separation to effectively remove contaminants from water. A concentrated sludge layer is then removed as a result of the system’s creation of microscopic air bubbles that stick to the suspended particles and cause them to float to the surface.

KEY FEATURES

- Efficient Solid-Liquid Separation: Fenton Technologies Dissolved Air Flotation System offers efficient solid-liquid separation, effectively removing suspended solids, oils, grease, and other contaminants from water. It ensures the production of clarified water with reduced turbidity and improved water quality.

- Optimized Bubble Generation: Our DAF system utilizes optimized bubble generation techniques to create fine air bubbles for effective particle attachment. This maximizes the flotation efficiency and enhances the removal of even the smallest particles from the water.

- Flexible Design Options: Fenton Technologies Dissolved Air Flotation System offers flexible design options to accommodate varying flow rates, water characteristics, and application requirements. It can be customized with different tank sizes, plate spacings, and sludge handling mechanisms to suit specific project needs.

- Enhanced Chemical Conditioning: Our DAF system incorporates advanced chemical conditioning processes to optimize coagulation and flocculation, enhancing the removal of contaminants. This ensures efficient solids separation and improved overall performance.

- Easy Operation and Maintenance: Fenton Technologies Dissolved Air Flotation System is designed for easy operation and maintenance. It features user-friendly controls, automatic sludge removal mechanisms, and accessible components for routine cleaning, inspection, and maintenance tasks.

- Rugged Construction: Our bar screens are constructed with high-quality materials, making them durable and resistant to corrosion. They can withstand harsh operating conditions and provide reliable performance over extended periods, minimizing maintenance requirements.

- Flexible Bar Spacing Options: Fenton Technologies Bar Screen offers flexible bar spacing options to accommodate different wastewater characteristics and flow rates. This adaptability allows for effective solid separation in a wide range of applications.

- Self-Cleaning Mechanism: Our bar screens are equipped with a self-cleaning mechanism, such as rotating brushes or spray jets, to remove captured solids from the bars. This feature ensures continuous operation without manual intervention, reducing downtime and optimizing efficiency.

- Easy Installation and Maintenance: Fenton Technologies Bar Screen is designed for easy installation and maintenance. It can be customized to fit specific channel dimensions and can be easily accessed for cleaning, inspection, and routine maintenance tasks.